Purpose and design of foam carbon dioxide freon fire extinguishers. Let's look at the features of different types of fire extinguishers

For information: advertising assurances from manufacturers/suppliers of chemical substances regarding the effective extinguishing of solid substances/materials (fire class A) contradict the standards established by the state; and calls to equip every car with them are common sense based on their cost. Unless, of course, it is a museum exhibit, a rare retro car or a car for executive class servants of the people. Although their use in airplanes, on river and sea vessels, in railway transport, including in the metro, is completely justified, expedient, and economically justified.

According to the standards for equipping premises of industrial and public buildings, OH should again be guided by adj. No. 1 to “PPR in the Russian Federation”, published in 2012:

- In workshops, production premises of categories A, B, C, with fire class B, C - 4 OX with a capacity of 2 (3) liters for every 200 sq. m.

- Category B, class E – 2 ОХ-2(3) per 400 sq. m.

- G, D, class E – 2 ОХ-2(3) per 1800 sq. m.

- In public buildings, class E - 4 OX-2(3) per 800 sq. m.

Note: if you evaluate the effectiveness of the types of fire extinguishers used to extinguish electrical installations; then, according to the above standards, the minimum required configuration of premises, different in purpose, fire class, OX is no less than 2 times more effective than OU.

The use of mobile chemical weapons weighing from 20 to 400 kg is not regulated by norms and rules established by the state, just as they are not encountered in practice, apparently due to the deliberate lack of possible demand due to the high cost of even hand-held devices.

Another significant use of freons for ensuring fire safety at protected industrial/civil facilities is as a fire extinguishing agent. in stationary automatic installations/gas fire extinguishing systems, as an effective alternative to traditionally used carbon dioxide.

You should know and remember: premises in one protected facility must, based on the physico-chemical properties of the fire load, i.e. furniture, combustible/combustible goods, raw materials, finished products; substances/materials involved in the technological process that are in replaceable or long-term storage; complete only one type of fire extinguisher of the 5 specified in PPR-2012: OVP, OP, OU, OVE (air emulsion) or OX.

It is unacceptable to use devices with different fire extinguishing compositions/substances at the same time; this is not only impractical, even pointless; but, depending on the specific situation, it can be simply dangerous - lead to repeated fires, destruction, damage to valuable equipment; expensive commercial products, therefore, to additional indirect damage from the fire.

In practice, based on the real, retail cost of the listed primary funds, the choice usually remains with the ORP, OP or OU, and even then, the latter type is exclusively for electrical installations, switchboards, and valuable equipment.

Freon and air-emulsion devices, the price of which is very significant and, in the author’s opinion, unreasonably inflated by manufacturers/sellers compared to other types of fire extinguishers, are rarely used; mainly for the protection of really important premises/objects or when their wholesale supply or packaging occurs at the expense of the state/large manufacturing, financial companies/corporations.

Classes of halon fire extinguishers are not clearly defined by the rules and regulations, but in fact they exist, depending on the type used to fill the OX liquefied gas mixture based on halogenated hydrocarbons. The list of such chemical substances, generally/briefly called in this case freons, is established by SP 5.13130.2009, which applies to both the fire extinguishing composition of gas fire extinguishing devices and portable chemical agents.

Operating principle of a freon fire extinguisher

- Chemical substances, compounds of the gas mixture from OX, entering the source, begin to decompose under the influence of high temperature with the appearance of free radicals.

- The latter actively react with primary combustion products, binding them into inert compounds.

- It is very important that this physical and chemical process is accompanied by the absorption of a large amount of heat.

- As a result of these factors, the combustion process rapidly slows down and the fire extinguishes; and with a sufficient concentration of the gas mixture in the area of the fire, its localization and complete elimination.

Scientific research shows that this method is more effective than supplying inert gases that do not support the combustion process - nitrogen, argon or carbon dioxide - to the fire.

Design and characteristics of a halon fire extinguisher

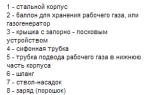

The OX includes the following elements (parts):

- A steel cylinder with a connecting thread, designed for high pressure, many times greater than the working pressure. Volume from 2 to 8 liters in accordance with the OX brands most common among manufacturers.

- A charge of refrigerant of one type or a recommended mixture, pumped in a liquid aggregate state under pressure into a cylinder.

- Locking device with a tap/lever with a stopper/safety device against accidental activation.

- Pressure indicator.

- Siphon tube for supplying refrigerant from the bottom of the cylinder.

- Hose with spray device.

A full check of a halon fire extinguisher must be carried out at a specialized enterprise that has a license from the Ministry of Emergency Situations for this type of work. About its implementation, information about the date of the event and the company responsible for this event is provided using a label/sticker or tag. Similar information is entered in the technical passport of each OH, as well as in the journal of their accounting at the enterprise where they are on the balance sheet.

According to SP 9.13130.2009, which establishes requirements for portable/mobile fire extinguishers, including their regular maintenance, the following shelf life and recharging times for the fire extinguisher are established:

- Checking the serviceability of components and parts, the main parameters of the OX - once a year, including by weighing to determine the possible loss of charge mass due to insufficient connection density or improper use, which is also not uncommon. The established maximum limit according to GOST R 51057-2001 for portable fire extinguishers is no more than 5% of the weight of the freon charge.

- Recharge – after 5 years from the production date.

You will also find it useful to read the following information:

Extinguishing with a halon fire extinguisher

The choice of chemical agents as the main operational fire extinguishing agent to protect the premises of an enterprise or organization is due to the following:

- High efficiency in its range of application - fires of classes B, C, E. The minimum concentration in the flame source is no more than 15%.

- Since freons do not conduct electric current, it is allowed to extinguish operating installations and equipment with voltage up to 10 kV with them, which greatly distinguishes them from carbon dioxide, for which the limit for such use is 1 kV.

- Of particular value is the absence of consequences for inventory items caught in the stream from the chemical agent.

- The design of such a fire extinguisher, despite the fact that this device is constantly under high operating pressure, is safe.

- Modern freon compositions, unlike their predecessors, are slightly toxic or completely safe for human health, to the delight of versatile environmentalists - and for the ozone layer of the planet.

- OX can be operated in a wide temperature range: from – 50 to + 50℃.

The rules for extinguishing with a halon fire extinguisher are simple:

- Its device does not require preliminary preparation.

- OX is always ready for immediate use in critical situations.

- Unlike an op-amp, upon startup, despite the name associated with a freezer, there is no sharp decrease in the temperature of the op-amp parts or the surrounding space, which eliminates the possibility of frostbite.

Since according to the required length of the jet of freons from OX-2 is at least 2 m, for OX-3 and larger volumes - 3 m, it is quite convenient for them to work, being at a fairly safe distance from the source of fire.

To summarize, we can say that this, of course, is not a universal, but extremely effective means of extinguishing possible fires of classes B, C, E, which has a high cost. However, the end, as a rule, justifies the means, therefore, to protect important objects, equipment, apparatus, and various combustible valuables, its acquisition is completely justified and advisable.

Designed to extinguish fires of flammable and combustible liquids, solids, live electrical installations and other materials, except alkali metals and oxygen-containing substances.

Halon fire extinguishers should be used in cases where fire extinguishing compounds that do not damage the protected equipment (computer centers, electronic equipment, museum exhibits, archives, etc.) are needed to effectively extinguish a fire. The industry produces manual, portable and stationary freon fire extinguishers.

The freon fire extinguisher is a metal body, the neck of which is closed with a membrane. A punch with a spring is mounted above it. To activate the fire extinguisher, you need to place it on a hard surface, pierce the membrane with a sharp blow on the punch button and direct the stream towards the flame. The OX disposable fire extinguisher is intended for extinguishing fires on vehicles: cars, boats, trolleybuses, fuel trucks, as well as for extinguishing fires in electrical appliances (household and industrial).

2.5 Powder fire extinguishers

They are currently most widespread. They are used to eliminate fires of gasoline, diesel fuel, varnishes, paints, wood and other carbon-based materials. Special purpose powders are used to extinguish fires and ignition of alkali metals, organosilicon and various spontaneously combustible substances. Gives good results when extinguishing electrical installations. Widely used in vehicles and production areas.

OPs are available in three types: manual, portable and stationary. The principle of operation of the fire extinguisher: when you press the trigger lever, the seal breaks and the needle rod pierces the membrane of the cylinder. The working gas (carbon dioxide, air, nitrogen) leaves the cylinder through a metering hole in the nipple and enters under the aerofoil through a siphon tube. In the center of the siphon tube (in height) there is a series of holes through which part of the working gas escapes and loosens the powder. Air (gas), passing through the layer of powder, loosens it and the powder, under the influence of the pressure of the working gas, is squeezed out through a siphon tube and thrown through a nozzle into the ignition source.

Figure 4 - OP powder fire extinguisher

To activate the fire extinguisher, you need to pull out the pin or latch, point the fire extinguisher or the barrel of the fire extinguisher at the fire, lift the lever up (or press the button to pierce the gas cylinder), and after 5 seconds begin to extinguish the fire. ![]()

In the working position, the fire extinguisher should only be held vertically, without turning it over.

Table 3

|

Quantity |

Submission time |

Range |

|||||||||||||

|

fire extinguishing |

pressure |

ejection, m | |||||||||||||

|

th substances |

(kgf/cm 2) at |

substances, not | |||||||||||||

|

exploitation |

|||||||||||||||

|

Powder fire extinguishers |

|||||||||||||||

|

Mobile |

|||||||||||||||

|

Gas generator powder |

|||||||||||||||

|

Universal powder |

|||||||||||||||

|

Stationary |

automatic powders | ||||||||||||||

When extinguishing a fire with powder fire extinguishers, it is necessary to take additional measures to cool heated elements of equipment or building structures.

Powder fire extinguishers should not be used to protect equipment that could be damaged by powder (electronic computers, electronic equipment).

The invention of gas fire extinguishers saved many facilities with electrical installations and expensive equipment. In particular, refrigerants have been used for decades, but over time their production has decreased several times. The reason for this is the effect of the fire extinguishing agent on the environment and human health. However, halon fire extinguishers remain one of the most effective fire extinguishing agents.

Application area

Due to the characteristics of its effect on substances and materials, freon is used for extinguishing:

Class C and B fires – combustion of petroleum products, paraffin, alcohol, glycerin and gaseous substances. Halon fire extinguishers are intended for extinguishing only as a last resort, when other means do not help to cope with the fire.

Electrical installations are usually extinguished with powder or carbon dioxide compounds. If there are not enough of them or it is extremely undesirable to damage the equipment, then it is permissible to use halon fire extinguishers.

The last item includes archives, laboratories and workshops with complex equipment, and museums. Freon is also suitable for extinguishing server rooms and computer classes. All these objects have in common expensive installations or equipment and the presence of securities. For example, after using gas fire extinguishers with freon, the paper does not get wet, which allows you to maintain the integrity of important documents.

Previously, they were mainly produced for transport. Recently they have been replaced by freon ones. The substance from a carbon dioxide fire extinguisher does not completely cover automobile components and components that need to be cooled and sealed from oxygen, and the powder damages the materials. The minimum volume of a refrigerant fire extinguisher cylinder for passenger cars and trucks is 2 liters. It is placed next to the driver so that in the event of a fire he can quickly reach it and activate it.

Restrictions on use

Contact of alkali with refrigerant is not allowed in any case: during extinguishing or storage. Also, these fire extinguishers should not be placed near heating devices (distance of at least 1 m) containing explosive substances. Transportation of refrigerant in containers is possible only in covered transport.

For all their advantages, halon fire extinguishers also have a lot of disadvantages. One of the most important factors is the negative impact on human health. Freon vapors cause difficulty breathing, irritation of mucous membranes, and noticeably worsen health. Contact with the skin of this substance leads to severe burns, and in the stomach - to toxic poisoning.

Based on the listed impacts, it is necessary to work with freon using personal protective equipment. Such fire extinguishers cannot be used in rooms without ventilation. They are also not used for extinguishing hot pipelines.

The use of freon is limited in many countries due to its destructive effect on the ozone layer. Thanks to developments in the chemical industry, it has been possible to create compounds that are less hazardous to the environment, but freon is still used in exceptional cases.

Today, freon is widely used in stationary fire extinguishing installations. This is justified for museums and archives. In addition, such a substance is much more expensive than its analogues, and the fire extinguisher must be filled in one click. That is, the refrigerant is not released from the cylinder in parts. The unspent supply of such a fire extinguishing agent is disposed of or regenerated by specialized enterprises. Such residue cannot be released into the atmosphere.

Freon in fire extinguishing installations retains its properties for 10 years after refilling. All containers, including fire extinguisher cylinders, are checked for rust, water, impurities and foreign substances. When they are detected, the container is cleaned and emptied.

Freon can be used at ambient temperatures from -20°C to 50°C. Such fire extinguishers and their filling work in any air humidity, precipitation, or wind.

Design and principle of operation

A halon fire extinguisher is identical in design to a carbon dioxide fire extinguisher. The only difference is reduced weight and dimensions. Gas fire extinguisher device:

Inside the housing, the freon is in a compressed state. When the shut-off mechanism is opened, gas escapes through the tube to the bell in the form of snow. The released substance covers a certain area, quickly cooling the surfaces and blocking the access of oxygen to them.

After use, the freon completely disappears, leaving any surface without traces of the fire extinguishing agent. Snow appears due to the expansion of gas at the moment of release. Before use, the safety pin must be pulled out and the seal, which is present on all fire extinguishers, removed. Place the sprayer horizontally in relation to the ground or floor in the room and activate the mechanism by pressing the lever.

Freon looks like a colorless liquid, heavy in weight. It is classified as safe in terms of possible fires or explosions.

Freon decomposition begins after it is heated to 400 °C. Only then does it become toxic due to the release of substances containing fluorine and bromine.

Halon fire extinguishers are marked in accordance with the general rules. In addition to the release date, the name of the manufacturer, GOST performance standards indicate the nominal charge volume of the fire extinguishing agent and the ambient temperature range for using the product. They also indicate classes, fire models and warnings prohibiting the use of halon fire extinguishers under certain conditions.

The packaging (if there is one) and the label of the fire extinguisher contain a lot of information that is incomprehensible to the consumer - abbreviations, pictograms, diagrams. Manufacturers of fire extinguishers mark their products with letters characterizing the type of fire extinguisher (OP, OU, OV, ORP, etc.), indicating the class of fires (A, B, C, B, D and E) and numbers indicating the mass of the fire extinguishing agent (FME).

Depending on the weight of fire extinguishers, fire extinguishers are divided into portable (hand-held) or mobile, weighing more than 20 kg. Mobile fire extinguishers are designed to protect large objects: gas stations, warehouses, shops. They can only be purchased in specialized stores or from manufacturers.

When choosing a fire extinguisher, you need to pay attention to what types of fires the fire extinguisher is designed to extinguish. The class and rank of the model fire is indicated on the fire extinguisher label.

Fire classes:

- Class A- Combustion of solids

- Class B- Combustion of liquid substances

- Class C- Combustion of gaseous substances

- Class D- Combustion of metals and metal-containing substances

- Class E- fires caused by electrical equipment malfunctions (short circuits, arcs, overloads), as well as violations of the rules of technical operation of electrical installations

To ensure that the fire extinguisher you choose does not let you down and does not fail in severe frost, in an unheated room or car, when choosing a fire extinguisher, you must take into account the climatic operating conditions and make sure that the temperature range of use of the fire extinguisher corresponds.

Depending on the type of fire extinguishing agent used, fire extinguishers are divided into:

- aquatic(OB);

- air-foam(ORP);

- powder(OP);

- carbon dioxide(OU)

- freon(OH);

- air emulsion(OVE).

Depending on the principle of creating the gas pressure necessary to release the fire extinguishing agent, fire extinguishers are divided into:

- injection fire extinguishing agents (Type Z);

- a high-pressure cylinder (Type B) is used to store liquefied or compressed gas;

- product with a gas-generating device (Type G).

Example of symbols for fire extinguishers:

OVE-6(z)-AVE- air emulsion fire extinguisher. Then the volume of OTV is indicated, in this case it is 6 liters (h)- The principle of creating gas pressure - injection, is indicated by the letter “z” (this is not a number). Suitable for extinguishing class fires A, B, E.

Which fire extinguishers are best? Let's figure out how they differ.

When choosing fire extinguishers, you need to take into account the features of their design and the class of the expected fire. There are several types of fire extinguishers, differing in the principle of impact on the source of fire, the extinguishing agent, efficiency, versatility of use, and, of course, price.

Powder fire extinguishers (OP)

Powder fire extinguishers- the most common and universal type of fire extinguisher in terms of application. Due to their low cost, their market share reaches 80% of the total. Depending on the purpose, powder compositions are divided into general-purpose powders (ABSE, VSE) and special-purpose powders, which are used to extinguish class D fires, and can be used to extinguish fires of other classes.

Despite their versatility and prevalence, powder fire extinguishers have significant disadvantages:

- high smoke and a significant decrease in the visibility of the source and exit routes due to the powder cloud formed during application.

- the need to use personal protective equipment in enclosed spaces

- powder contamination of the protected object that is difficult to remove

- Fire extinguishing powders are prone to clumping and caking during storage.

- lack of cooling effect when extinguishing

- high probability of re-ignition of an already extinguished source from a heated object.

When extinguishing with a powder fire extinguisher (OP), high smoke content of the extinguishing object occurs due to a powder cloud

Gas fire extinguishers: carbon dioxide and freon.

Carbon dioxide fire extinguishers (CO)

Liquefied carbon dioxide (carbon dioxide) is used as a fire extinguishing agent in OS fire extinguishers. The effectiveness of flame extinguishing is achieved by cooling the combustion zone and displacing oxygen with non-flammable carbon dioxide.

The main advantages of such fire extinguishers are: efficiency in extinguishing liquid and gaseous substances (class B, C) and electrical installations up to 1000 V (class E), complete absence of traces of extinguishing, since carbon dioxide completely evaporates after use, leaving no traces. Carbon dioxide (CO2) is liquefied in a high-strength steel housing under high pressure, which is why all carbon dioxide fire extinguishers are heavier than other types of fire extinguishers.

Due to high pressure, carbon dioxide fire extinguishers should not be stored near heat sources or exposed to direct sunlight.

When using a carbon dioxide fire extinguisher, it is strictly forbidden to touch the fire extinguisher socket, because Carbon dioxide, when transitioning from a liquid to a gaseous state, instantly cools the fire extinguisher nozzle to -70 ° C.

Advantages of carbon dioxide fire extinguishers:

- efficiency of extinguishing liquid and gaseous substances (class B, C) and electrical installations under voltage up to 1000 V;

- no traces of extinguishing;

- operating temperature range from -40 °C to +50 °C

Disadvantages of carbon dioxide fire extinguishers:

- heavy weight of the fire extinguisher;

- the possibility of significant thermal stresses arising as a result of sudden cooling of the extinguishing object;

- the possibility of frostbite on the hands due to the sudden cooling of the fire extinguisher socket and cylinder;

- accumulation of static electricity charges on the fire extinguisher during use;

- the use of carbon dioxide fire extinguishers in a confined space leads to a sharp increase in CO 2 concentration, which can cause oxygen deficiency and suffocation;

- reduction in the effectiveness of the fire extinguisher at subzero temperatures.

- not used for extinguishing wood and substances that burn without air access (cotton, pyroxylin)

Halon fire extinguishers (OH)

Fire extinguishers based on freons are highly effective and are used where damage to protected equipment or objects is not allowed: data centers, server and communication equipment, electronic equipment, museum exhibits, archives, etc.).

Advantages of freon fire extinguishers:

- high efficiency of freon, 2 times higher than the efficiency of carbon dioxide;

- no destructive effect on extinguishing objects;

Disadvantages of freon fire extinguishers:

- toxic effects of freon and its pyrolysis products in a fire on the human body; - increased corrosiveness of freon;

- the possibility of destruction of the ozone layer;

- negative impact on the environment, impact on the ozone layer.

Water fire extinguishers (WF)

Water fire extinguishers are well suited for extinguishing the fire of solid flammable substances, materials of organic origin, the combustion of which is accompanied by smoldering, for example, paper, wood, rags (class A).

Advantages of water fire extinguishers:

- environmental cleanliness and safety for people;

- minor secondary damage from spilled water

Disadvantages of water fire extinguishers:

- water fire extinguishers cannot be used to extinguish flammable liquids (class B)

- water conducts electricity well and is not used to extinguish electrical fires (class E);

- narrow operating temperature range in which use is possible (from +5°C to +50°C)

Air-foam fire extinguishers (AFP)

IN air-foam fire extinguishers The extinguishing agent is foam. It consists almost entirely of air (the proportion of air contained in the foam reaches 90%). They are used to extinguish the initial stages of fire of solid or liquid substances, such as wood, oils, etc.

Disadvantages of air foam fire extinguishers:

- air-foam fire extinguishers cannot be used to extinguish flammable liquids in an area larger than 1 m² (class B)

- are not used to extinguish electrical fires (class E);

- narrow operating temperature range in which use is possible (from +5°C to +50°C);

- possibility of damage to the extinguishing object;

- high corrosive activity of the charge;

- annual recharging is required.

Chemical foam fire extinguishers (CFF)

Despite the improvements that have been made, they are obsolete and have low fire extinguishing ability and are gradually being taken out of service and replaced with more effective fire extinguishers. They are used to extinguish solid flammable substances (class A). Their only advantage is their low cost.

Air emulsion fire extinguishers (AFE)

Air emulsion fire extinguishers (AFE) incorporate the advantages inherent in water and air-foam fire extinguishers, but lack their main disadvantages. OVE fire extinguishers use the injection principle. The water-based fire extinguishing agent (WFA) is safe for humans and the environment, as confirmed by sanitary and epidemiological conclusions. OVE fire extinguishers allow you to immediately begin extinguishing a fire in enclosed spaces before the evacuation of people without the use of personal respiratory and visual protection. The use of OVE fire extinguishers does not reduce visibility in the fire zone. It can be used to extinguish fires in enclosed spaces in the presence of people without the use of personal protective equipment. No secondary damage from spillage or contamination of the facility with fire extinguishing agent, due to minimal consumption of fire extinguishing agent.

Fire extinguishers OVE They are universal and are used to extinguish fires in premises, transport, and outdoors, including at negative air temperatures down to minus 40 ° C.

Due to the high stability of the fire extinguishing agent solution, the service life of air-emulsion fire extinguishers is 10 years without recharging and re-examination.

Advantages of air emulsion fire extinguishers:

- high efficiency of extinguishing solid flammable substances, materials of organic origin, the combustion of which is accompanied by smoldering, and flammable liquids (class A, B);

- possibility of extinguishing live electrical installations and electrical equipment up to 20,000 V(class E);

- effective cooling of the combustion source;

- absence of secondary damage from exposure to the fire extinguishing agent;

- operating a fire extinguisher at temperatures as low as minus 40 °C;

- the long service life of a fire extinguisher without recharging and re-examination is 10 years;

- 40 recharges of the fire extinguisher are allowed over the entire service life;

- environmentally friendly and safe

- fire extinguisher is universal in use

One OVE-5 (air-emulsion) fire extinguisher surpasses 20 OVP-5(z) (air-foam) fire extinguishers in its fire extinguishing capabilities of solid combustible substances.

Disadvantages of air emulsion fire extinguishers:

- relatively high cost.

As a rule, it is air emulsion fire extinguishers, due to the combination of high efficiency characteristics, they become the choice of professionals, reputable organizations and departments, as well as ordinary citizens who highly value their safety, the safety of their loved ones and the safety of their property.

After using a fire extinguisher, it must be recharged. Up to 40 recharges are allowed during the service life.

The higher price, compared to other types of fire extinguishers, is justified by the high reliability and efficiency of air-emulsion fire extinguishers.

The fire extinguishing ability of the OVE-5 fire extinguisher when extinguishing solid flammable substances (class A) is comparable to the fire extinguishing ability of the OVP-100(z) air-foam fire extinguisher or the OP-50(z) powder fire extinguisher, and when extinguishing liquid flammable substances, the OVE-5 fire extinguisher is - similar to OVP-50(z), or OP-20(z). There is no need for re-inspection and recharging during the life of the fire extinguisher, saving your money and time.

A halon fire extinguisher is characterized by high efficiency in suppressing flames, but recently the scope of use of this type of device has been significantly limited. The reason for this is the resolving effect of freon on the ozone layer of the planet.

For what purposes are halon fire extinguishers used?

The use of an aerosol method of flame suppression makes this type of fire-fighting equipment universal in relation to the scope of use. Thus, freon fire extinguishers are designed to extinguish fires of the following classes:

- B – flammable liquids, including oil, derivative products and fuels and lubricants;

- C – gaseous explosive atmospheres;

- E – electrical equipment.

It is necessary to add that extinguishing electrical devices is permissible only in the first minutes of a fire. To specify the situation regarding the cases in which halon fire extinguishing agents should be used, we highlight the following places:

- Warehouses, other places where finished products and other material assets are stored;

- production workshops with high-tech equipment;

- libraries or archive rooms;

- communication and control centers.

This choice is due to the fact that it is possible to extinguish objects without further damaging them with the reagent: the gaseous hydrocarbon mixture simply evaporates from the objects being processed. Thus, all valuable items that survived the fire, including documentation, will not be damaged by the effects of the fire extinguishing agent.

In addition to trains and public transport, they are installed in personal cars, replacing outdated models with powder or carbon dioxide filler. The advantages of freon over them are the absence of contamination of the interior and engine compartment, the ability to penetrate hard-to-reach cracks between car components, as well as the light weight of the product, its resistance to vibration and mechanical shock.

Freon fire extinguishers - technical characteristics

The main operational parameters of the device are:

- weight, range of the jet and release time of the fire extinguishing agent;

- operating temperature range, as a rule, from -20 to +60 0 C;

- maintained pressure of 1 – 1.5 MPa;

- an inert gas, usually nitrogen.

The first three characteristics are grouped together because they are directly related to the capacity of the fire extinguishing device. For example, an OX 2 freon fire extinguisher, where the number determines the amount of extinguishing agent in liters, has a weight of about 4 kilograms, an effective jet length of 2 meters and 6 seconds for the release of the main substance. A threefold increase in capacity is characterized by an increase in all three parameters. Thus, the OX 6 halon fire extinguisher already weighs 11 kg, has a “range” of 4 meters and requires up to 10 seconds of time to get rid of the fire extinguisher.

In fact, the capacity of the device also determines the scope of application of the halon fire extinguisher - its purpose. For example, for motorists, an OX 4 freon fire extinguisher may already be “heavy”, its weight is about 7 kg, which is significantly greater than a 4-kilogram 2-liter device. However, when choosing an extinguishing agent, it is necessary to proceed from the fact that the fire extinguishing agent is sufficient to extinguish the fire.

Fire extinguishing agent

As mentioned earlier, the main component of the device that suppresses the flame is freon. It is a gaseous hydrocarbon mixture, known to many as a coolant inside refrigeration units. The world community's concern about the harmful environmental effects of freon has become the reason for modifying its composition. Modern freon fire extinguishers made in Slovakia or Russia are charged with a mixture of FE-36 or the Russian name OTV “freon 236”, also known as 1,1,1,3,3,3-Hexafluoropropane. Its difference from the “dangerous freon” is the absence of chlorine and bromine atoms, which eliminates the destruction of the ozone layer.

Alternatively, OTV R-236 has a number of other advantages:

- low level of toxicity;

- does not cause corrosion;

- is a dielectric;

- there is no sediment after evaporation.

This allowed him to rapidly rise upward, even in the literal sense of the word. Today, halon fire extinguishers based on FE-36 can be found even on board an Airbus.

Installation of a freon fire extinguishing agent

The circuit of a freon fire extinguisher is similar to a carbon dioxide apparatus. In fact, this is a siphon-type installation that spews out refrigerant due to the creation of excess pressure. The siphon tube penetrates the entire body of the fire extinguisher from the inside, only just short of reaching the bottom of the cylinder. The end of the tube is connected to the charging and starting device. Opening the valve forces the refrigerant out of the apparatus with pressure, while the exhaust gas at the outlet is transformed from a liquid state into fine “snow”. This mass covers the source of ignition, blocks the access of oxygen there and stops combustion.

An important detail: freon fire extinguishers are characterized by almost two times lower internal pressure than carbon dioxide analogues, which reduces their weight and also makes the devices safe for use in transport.

Use and subsequent maintenance of the device

The technique for using fire extinguishing agents is clearly displayed on the devices themselves. However, it is worth recalling that a freon fire extinguisher is not only simple, but also safe to use. In particular, there is no risk of burns due to frostbite or static electricity. The low level of toxicity does not require leaving the room immediately; it is enough to open the windows after the fire is extinguished.